As a project developer and trading firm of physical goods, we offer sourcing and development of standard as well as customized commodities and goods, which are critical to vehicle safety, energy production etc. This requires much more than simply locating specific materials or services that our customers need for their value chain. It is essential for us and a given fact that we make no compromises, when it comes to quality. We are extremely careful in our selection of partners, and we also make substantial investments in their development. At the same time it is necessary to build a logistics concept that ensures an optimal flow of materials, taking into account factors such as availability, stocks, flexibility, lead times,transportation costs and financing. All those aspects together ultimately determine the success of sourcing.

PRODUCT DEVELOPMENT

PRODUCT DEVELOPMENT

For each customer, we define a strategy that develops a supplier base to meet their individual needs and service requirements. Mellon Technology is responsible for sourcing all commodities, articles and components. Besides basic raw materials and standard goods, which require mostly logistical and financial competence, we develop components that are specifically designed and optimized for their application and are used to a great extent in the industrial sector. Our specialists in technical consulting services work with our customers to develop customized solutions for their requirements and accompany them throughout the entire process of development, first sample, batch production. We continuously evaluate the market for the required spectrum of parts and/or services, and constantly ensure that our established supplier base provides the optimum in terms of quality, delivery and cost performance.

QUALITY MANAGEMENT

QUALITY MANAGEMENT

We place highest value on the quality of our products, processes and services. Our quality philosophy is evident in our everyday business, modern quality methodes, such as Kaizen, Ishikawa/risk analyses, Taguchi methods and FMEA are used for support. An extensive selection of test equipment is available for product verification. Our quality engineers are very pro-active in supplier quality management, in monitoring supplier products and processes at great length and detailed. Application engineering, consultation and product range optimization are carried out, incorporating a very high level of quality. As a reliable partner, we supply various industries including the automotive, machinery and energy industry. The quality of our products, can be tracked all the way back to the part numbers of their components, while the performance of our suppliers is continuously assessed and improved.

FORGING

FORGING

Forging has been used as a metalforming process for milleninia and is a major worldwide industry today due to its diverse applications in various industries, where components require high strength. Processing raw material through forging is a very competitive process to form any kind of metal into t

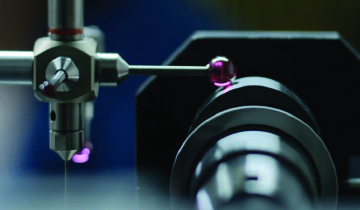

MACHINING

MACHINING

We perform all kinds of machining operations from turning, milling, drilling to all kind of miscellaneous operations like burnishing and final assembling. Components are specifically designed and produced for their respective application in the industrial sector. In the pre-development and productio

© Copyright Mellon Technology 2017